Chinese-funded PCB output value dominates warning, experts: Chinese factories are eager to pursue semiconductor independence

TechNewsTechnology News

November 20, 2024

Author: Central News Agency reporter Jiang Mingyan

November 20, 2024

Author: Central News Agency reporter Jiang Mingyan

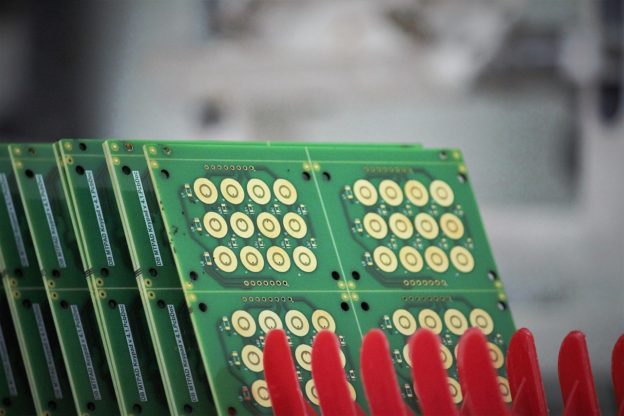

China's printed circuit board (PCB) output value may overtake Taiwan this year and become the world's largest. Qiu Shifang, an analyst at the National Taiwan Institute of Economics, believes that China has its own brands exporting to the sea. Under the domestic substitution policy, profits are not the primary consideration. In response to the autonomy of semiconductors, Chinese manufacturers are stepping into IC substrates, although they are still some way behind the leading Taiwanese manufacturers. gap, but future competition cannot be ignored.

The Taiwan Circuit Board Association (TPCA) and the Institute of Obstetrics and Technology of the Industrial Research Institute recently released the "2024 Mainland China PCB Industry Dynamics Observation". It is estimated that the output value of Chinese PCB will grow rapidly to US$26.79 billion in 2024, an annual increase of 16.6%, and the global market share It will increase to 32.8%, which may overtake Taiwan manufacturers in one fell swoop and become the first in the world in PCB output value.

Qiu Shifang, an analyst at the Taiwan Economic Research Institute's Industrial and Economic Database, told a reporter from Central News Agency that output value means large scale and is an indicator of market influence. Therefore, many industries in China strive to increase revenue and scale.

She further said that for Taiwanese factories, profit is the first consideration; while the more important goal of Chinese factories is to comply with policy requirements. Under state subsidies, profits may not be the primary consideration, and Chinese factories may compete through price cuts. Methods to obtain orders in order to pursue scale, and more importantly, to respond to the goal of "domestic substitution". For example, more funds will be invested in the research and development of high-end products to replace components originally purchased from overseas manufacturers, or the government may require that domestically produced cars must purchase a certain proportion of local components.

In addition, Qiu Shifang pointed out that PCB rigid boards are the most important product for China, and its advantage comes from China’s large exports to the sea in mobile phones, automobiles and other fields. Apple previously adopted a red supply chain. As Chinese factories invested in HDI and soft boards, it squeezed out the business of Taiwanese factories. However, in recent years, many Taiwanese factories such as Huatong, Jianding, Yaohua, Jinxiang Electronics, etc. have successfully transformed and have shifted from relying on mobile phones in the past. Mainly application orders, spanning into more new fields such as AI servers, low-orbit satellites, and automotive HDI.

TPCA pointed out that in order to promote the independence of the semiconductor industry, China launched the third phase of the "National Grand Fund" and listed AI chips and high-bandwidth memory (HBM) as core investment directions; as China promotes the independence of domestic chips, it will further promote enhance the growth of its carrier board business.

In the field of new energy vehicles, TPCA pointed out that China-made new energy vehicles account for more than 60% of the world's total. Government policies not only include car purchase subsidies and tax exemptions, but also further require car manufacturers to prioritize the use of local supply chains, which will help improve Market share of Chinese PCB manufacturers.

Domestic carrier board trio Xinxing, Nandian and Jingshuo have technological leadership. Will they face competition from Chinese manufacturers in the future? Qiu Shifang said frankly that originally the leading manufacturers of IC carrier boards were Taiwan, Japan, and South Korea. However, in order to meet the demand for independent semiconductors, Chinese factories accelerated their catch-up and made rapid progress. For example, Shennan Circuits and Xingsen Technology have entered the IC carrier market. plate.

She further said that the technical level of IC carrier boards is inherently higher than that of traditional PCBs. The fields that Chinese factories initially entered were mainly BT carrier boards, and the application terminals were mobile phones, wearable devices, memories, etc. As Chinese manufacturers have recently significantly expanded memory production capacity, the manufacturing rate can also increase with the support of demand.

Among IC carrier boards, ABF carrier boards have a higher technical level. From 2020 to 2022, due to insufficient production expansion and low yield rates, there will be a wave of ABF supply shortage and product price increases.

Qiu Shifang pointed out that Chinese factories are currently investing in ABF carrier board production capacity, but the technology has not yet made a breakthrough, and production capacity and yield are limited. "There is still a certain gap between Chinese factories and factories in Taiwan, Japan and South Korea"; but in the future, the production capacity of Chinese factories will be expanded. Later, it is estimated that it will be used first in ABF carrier boards with mature processes, such as PC, Netcom, and automotive parts. The ABF carrier board production capacity of Taiwan and Japan factories will give priority to supplying servers and high-end switches with better profits.

Qiu Shifang believes that currently "there are considerable differences in product positioning and main customers" between Taiwanese and Chinese manufacturers, but we must face up to the catching up of Chinese manufacturers and the competition they may face in the future.

【Disclaimer】

The content of this article only represents the author’s personal views and has nothing to do with Creating.

The content, textual description and originality have not been confirmed by this site. This site does not make any guarantee or commitment for this article and all or part of its content, authenticity, completeness, and timeliness. It is for readers' reference only. Please verify the relevant content by yourself.

Creating Nano Technologies, Inc.

59 Alley 21 Lane 279, Chung Cheng Road, Yung Kang City, Tainan, TAIWAN

TEL:886-6-2323927 FAX:886-6-2013306 URL: http://www.creating-nanotech.com