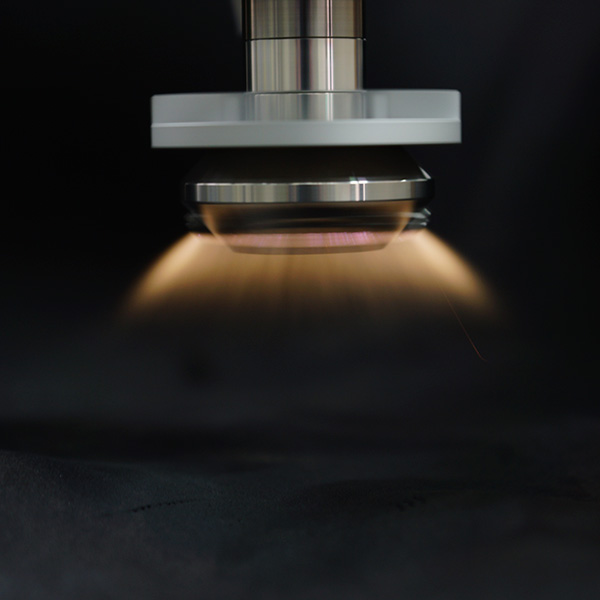

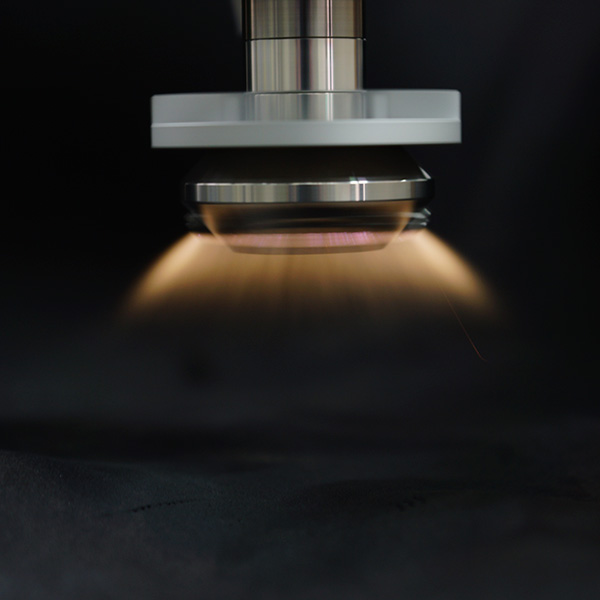

AP Plasma

Rotation Type SAP033RZ/SAP033RT/SAP033XR

Production Description

Operates under ambient conditions to rapidly remove organic contaminants, achieving both surface cleaning and modification.

Effectively enhances bonding, packaging, and printing reliability, serving as an alternative to traditional flame treatment.

The rotary nozzle design further extends the treatment area, improving process efficiency and uniformity.

Effectively enhances bonding, packaging, and printing reliability, serving as an alternative to traditional flame treatment.

The rotary nozzle design further extends the treatment area, improving process efficiency and uniformity.

Product Features

- Operates under ambient conditions to rapidly remove organic contaminants and modify surfaces.

- Enhances bonding, packaging, and printing reliability, serving as an alternative to flame treatment.

- Rotary nozzle design extends the treatment area and improves plasma efficiency.

- Integrates with continuous production lines for seamless, automated operation.

- Supports cost-effective CDA (SAP033RT / SAP033XR) or N₂ gas (SAP033RT) as the working gas.

- Interchangeable nozzles allow flexible adjustment of the treatment range.

- Ideal for 3D component processing.

Related solutions

- Power battery industry

- Automotive, motorcycle, and bicycle manufacturing

- Footwear industry

- Surface cleaning, activation, and modification for various materials such as printed circuit boards (PCB), glass substrates, and plastic substrates